ENGINEERING

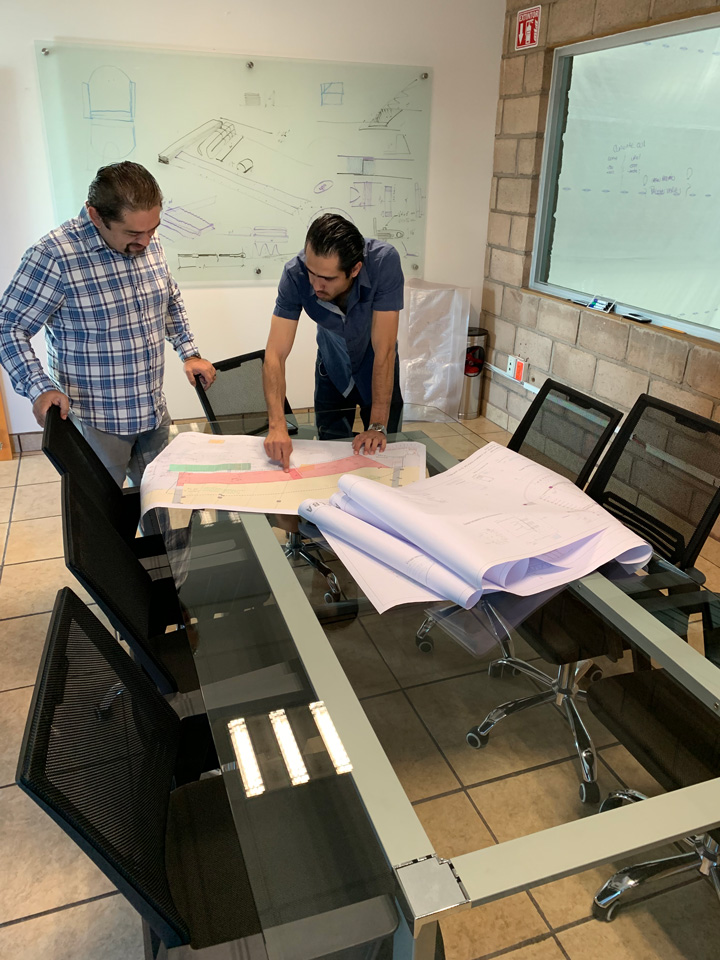

Span Flex’s dedicated team of specialty engineers, designers and engineering consultants are extremely experienced and knowledgeable, working with the industry's latest custom tensile architectural materials and steel cable structure systems.

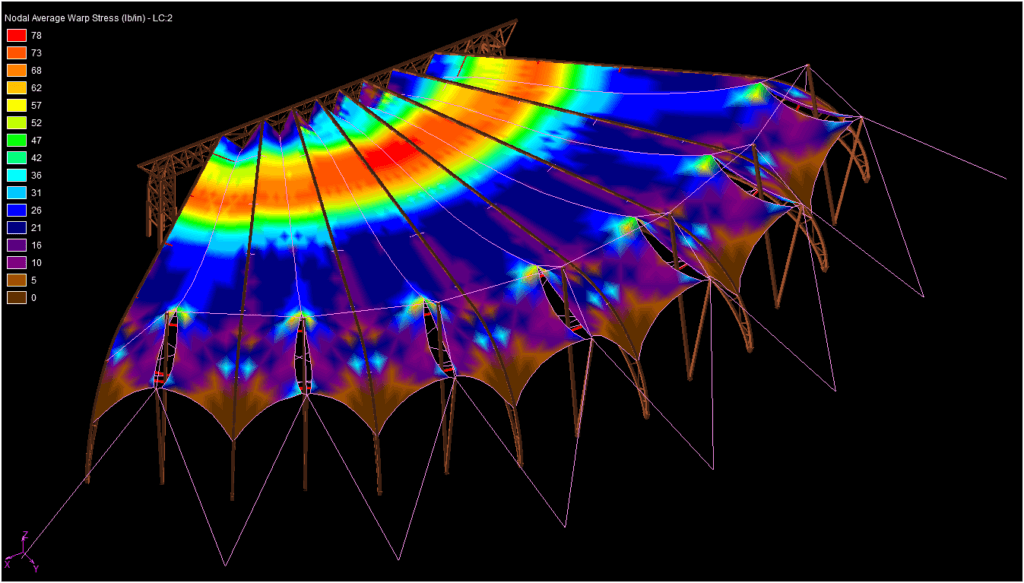

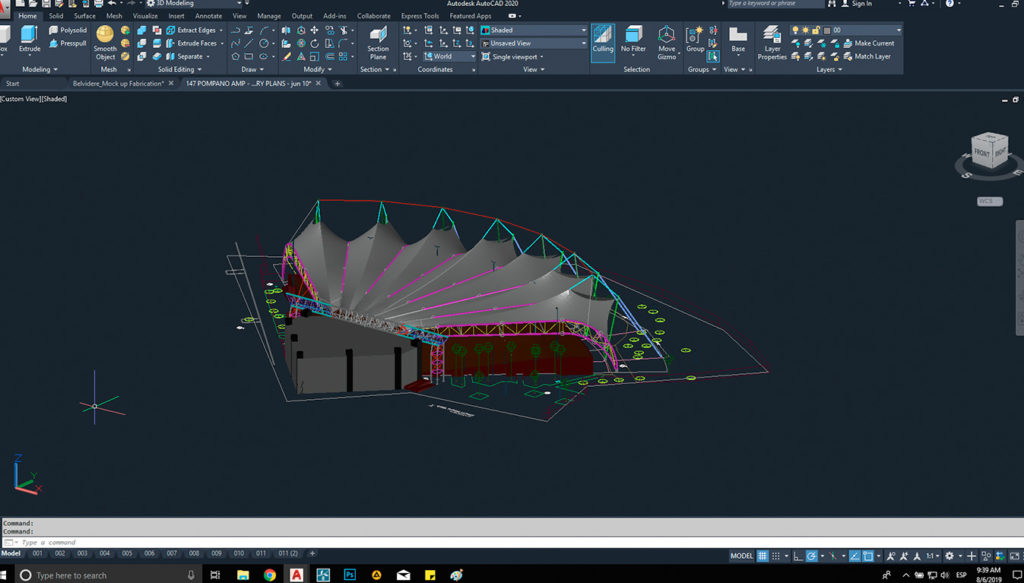

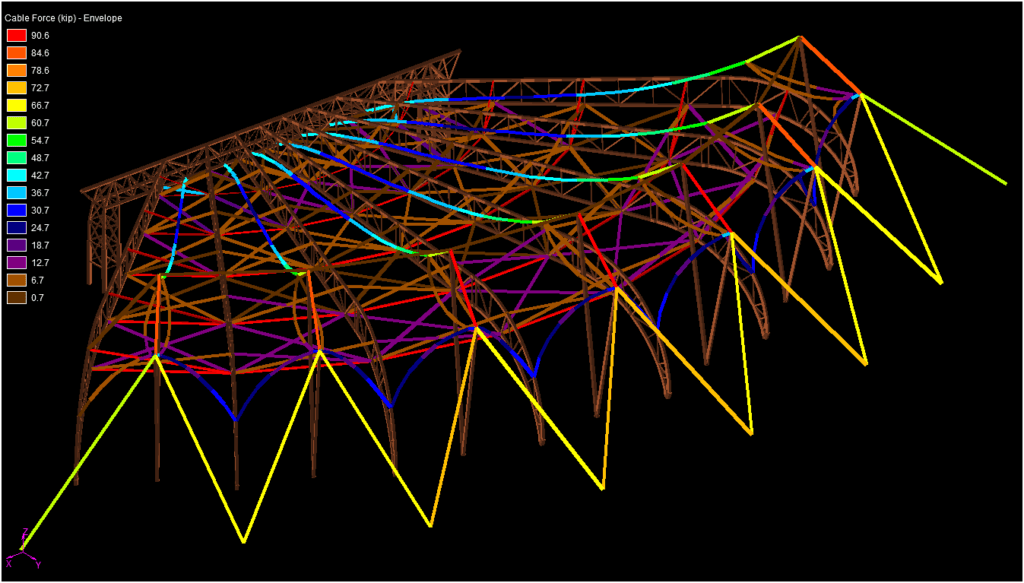

Through design/ engineering analysis based on the required design load criteria (i.e, wind, snow, gravity, etc.) with the most modern and sophisticated finite element analysis (FEA) software and peer review, Span Flex analyzes fabric stresses, cable tensions, delivers reaction loads, connection details, member sizing, interface details and construction methodologies.

Once the engineering submittals are approved by the architect/client, we proceed with a final set of calculated and patterned shop drawings for final fabrication and manufacturing. “Patterning” is the art of representing three-dimensional shapes by connecting a series of flat, two-dimensional templates into one fabric assembly.

As a result, the Span Flex team delivers an efficient high-quality tensile fabric structure or facade unmatched in the tension membrane structures industry.